Find Your Powder

Our Hardfacing Product Finder tool quickly identifies the ideal solution based on industry, application, and performance requirements.

Filter Results

Found materials matching your search input.

Showing 61–72 of 105 results

-

Colmonoy® 62C

Nickel-Based Hard-Surfacing Alloy for Wear, Corrosion, Heat, and Galling ResistanceDESCRIPTIONFor use on new parts to resist against wear, corrosion, hear and galling. Also use for repair of worn or out of tolerance parts.APPLICATION METHODS- Fusewelder™ Torch

- Thermal Spray / Spraywelder™

TYPESNickelWCL56-63 -

Colmonoy® 62H

Nickel-Based Hard-Surfacing Alloy for Wear, Corrosion, Heat, and Galling ResistanceDESCRIPTIONFor use on new parts to resist against wear, corrosion, hear and galling. Also use for repair of worn or out of tolerance parts.APPLICATION METHODSHVOF/HVAFTYPESNickelWCL56-63 -

Colmonoy® 62M

Nickel-Based Hard-Surfacing Alloy for Wear, Corrosion, Heat, and Galling ResistanceDESCRIPTIONFor use on new parts to resist against wear, corrosion, hear and galling. Also use for repair of worn or out of tolerance parts.APPLICATION METHODS- Fusewelder™ Torch

- Thermal Spray / Spraywelder™

TYPESNickelWCL56-63 -

Colmonoy® 62P

Nickel-Based Hard-Surfacing Alloy for Wear, Corrosion, Heat, and Galling ResistanceDESCRIPTIONFor use on new parts to resist against wear, corrosion, hear and galling. Also use for repair of worn or out of tolerance parts.APPLICATION METHODS- Laser Cladding

- PTA

TYPESNickelWCL56-63 -

Colmonoy® 62SA

Nickel-Based Hard-Surfacing Alloy for Wear, Corrosion, Heat, and Galling ResistanceDESCRIPTIONFor use on new parts to resist against wear, corrosion, hear and galling. Also use for repair of worn or out of tolerance parts.APPLICATION METHODS- Fusewelder™ Torch

- Thermal Spray / Spraywelder™

TYPESNickelWCL56-63 -

Colmonoy® 63

Nickel-Based Hard-Surfacing Alloy for Wear, Corrosion, Heat, and Galling ResistanceDESCRIPTIONUsed for hardsurfacing new parts to resist wear, corrosion, heat and galling. Also used for repair of worn or out of tolerance parts.APPLICATION METHODS- Fusewelder™ Torch

- Thermal Spray / Spraywelder™

TYPESNickelWCC56-63 -

Colmonoy® 63 HV

Nickel-Based Hard-Surfacing Alloy for Wear, Corrosion, Heat, and Galling ResistanceDESCRIPTIONUsed for hardsurfacing new parts to resist wear, corrosion, heat and galling. Also used for repair of worn or out of tolerance parts.APPLICATION METHODSHVOF/HVAFTYPESNickelWCC56-63 -

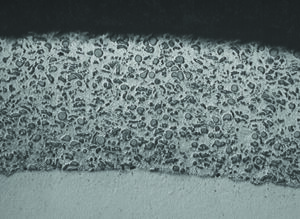

Colmonoy® 635

Nickel-Based Spray & Fuse Composite Alloy with Excellent Tungsten Carbide Deposit EfficiencyDESCRIPTIONContains both crushed an atomized powders.. A unique property of the tungsten carbide particles is that it allows for a metallurgical bond with the matrix, rather than just the mechanical encapsulation common in other composite materials.APPLICATION METHODS- Fusewelder™ Torch

- Thermal Spray / Spraywelder™

TYPESNickelGlobal57-63 -

Colmonoy® 63B

Nickel-Based Hard-Surfacing Alloy for Wear, Corrosion, Heat, and Galling ResistanceDESCRIPTIONFor use on new parts to resist against wear, corrosion, hear and galling. Also use for repair of worn or out of tolerance parts.APPLICATION METHODSFusewelder™ TorchTYPESNickelWCL56-63 -

Colmonoy® 63F

Nickel-Based Hard-Surfacing Alloy for Wear, Corrosion, Heat, and Galling ResistanceDESCRIPTIONFor use on new parts to resist against wear, corrosion, hear and galling. Also use for repair of worn or out of tolerance parts.APPLICATION METHODSFusewelder™ TorchTYPESNickelWCL56-63 -

Colmonoy® 64

40% Agglomerated Tungsten Carbide in a Ni-Cr-B Matrix for All Combusion Thermal Spray SystemsDESCRIPTIONA unique composite material containing a moderately high volume percent of extremely abrasion resistant tungsten carbide particles in an abrasion resistant nickel-based matrix alloy.APPLICATION METHODS- Fusewelder™ Torch

- Thermal Spray / Spraywelder™

TYPESNickelGlobal58+ -

Colmonoy® 686

Outstanding Resistance to Pitting Corrosion Applicatino by PTA, Laser, and HVOF TechniquesDESCRIPTIONA nickel-based superalloy with high levels of chromium, molybdenum, and tungsten, achieving one of the highest ratings possible for pitting corrosion resistance.APPLICATION METHODS- HVOF/HVAF

- Laser Cladding

- PTA

TYPESNickelGlobal99 (B)