Find Your Powder

Our Hardfacing Product Finder tool quickly identifies the ideal solution based on industry, application, and performance requirements.

Filter Results

Found materials matching your search input.

Showing 49–60 of 105 results

-

Colmonoy® 56P

Nickel-Based Hard-Surfacing Alloy to Resist Abrasion, Corrosion, Hear and GallingDESCRIPTIONHigh levels of chromium and carbon produce large populations of chromium carbides for superior abrasion and corrosion resistance.APPLICATION METHODS- Hardfacing Rod

- Hardfacing Wire

- Laser Cladding

- PTA

TYPESNickel -

Colmonoy® 56SA

Nickel-Based Hard-Surfacing Alloy to Resist Abrasion, Corrosion, Hear and GallingDESCRIPTIONHigh levels of chromium and carbon produce large populations of chromium carbides for superior abrasion and corrosion resistance.APPLICATION METHODS- Fusewelder™ Torch

- Thermal Spray / Spraywelder™

TYPESNickelWCL50-55 -

Colmonoy® 6000

Gas Atomized Nickel-Based Hard-Surfacing Alloy to Resist Wear, Corrosion, Heat and Galling, Lower Level of Chromium Make it Ideal to Fuse Larger Parts.DESCRIPTIONThe lower level of chromium makes it easier to fuse larger parts.APPLICATION METHODS- Fusewelder™ Torch

- Thermal Spray / Spraywelder™

TYPESNickelGlobal56-62 -

Colmonoy® 6001

Water Atomized Nickel-Based Hard-Surfacing Alloy to Resist Wear, Corrosion, Heat and GallingDESCRIPTIONVery popular in the "oil patch".APPLICATION METHODS- Fusewelder™ Torch

- Thermal Spray / Spraywelder™

TYPESNickelGlobal58+ -

Colmonoy® 6002

Nickel-Based Hard-Surfacing Alloys for Restoring Worn PartsDESCRIPTIONAn atomized Ni-Cr-B-Si-Fe-C alloy powder sized to facilitate use in thermal spray applications by conventional combusion spraying or HVOF sprayingAPPLICATION METHODS- HVOF/HVAF

- Thermal Spray / Spraywelder™

TYPESNickelGlobal60+ -

Colmonoy® 6003

Atomized Nickel-Based Hard-Surfacing Alloy to Resist Wear, Corrosion, Heat and GallingDESCRIPTIONLower level of chromium makes it easier to fuse smaller parts.APPLICATION METHODSThermal Spray / Spraywelder™TYPESNickelGlobal56+ -

Colmonoy® 6006-505 HV

Composite Powder Containing 50% of a Ni-Cr-B-Si-Fe-C Matrix and 50% Tungsten CarbideDESCRIPTIONDesigned for superior wear resistance in demanding applications.APPLICATION METHODSHVOF/HVAFTYPESNickelGlobal>900 HV -

Colmonoy® 62 DJ

Nickel-Based Hard-Surfacing Alloy for Wear, Corrosion, Heat, and Galling ResistanceDESCRIPTIONUsed for hardsurfacing new parts to resist wear, corrosion, heat and galling. Also used for repair of worn or out of tolerance parts.APPLICATION METHODSHVOF/HVAFTYPESNickelWCC56-63 -

Colmonoy® 62 SA

Nickel-Based Hard-Surfacing Alloy for Wear, Corrosion, Heat, and Galling ResistanceDESCRIPTIONUsed for hardsurfacing new parts to resist wear, corrosion, heat and galling. Also used for repair of worn or out of tolerance parts.APPLICATION METHODS- Fusewelder™ Torch

- Thermal Spray / Spraywelder™

TYPESNickelWCC56-63 -

Colmonoy® 62 SM

Nickel-Based Hard-Surfacing Alloy for Wear, Corrosion, Heat, and Galling ResistanceDESCRIPTIONUsed for hardsurfacing new parts to resist wear, corrosion, heat and galling. Also used for repair of worn or out of tolerance parts.APPLICATION METHODS- Fusewelder™ Torch

- Thermal Spray / Spraywelder™

TYPESNickelWCC56-63 -

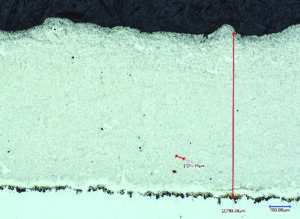

Colmonoy® 6200-402

Nickel-Based Spray & Fuse Composite Alloy with a -53+20 μm Carbide to Resist Fine Particle Abrasion and Promote FinishingDESCRIPTIONA composite hard-surfacing alloy contatining both atomized and crushed powders.APPLICATION METHODS- Fusewelder™ Torch

- Thermal Spray / Spraywelder™

TYPESNickelGlobal57-63 -

Colmonoy® 625

Excellent Corrosion Resistance, Outstanding Strength and Toughness at High TemperaturesDESCRIPTIONAn alloy with high fatigue strength and toughness.APPLICATION METHODS- Additive Manufacturing

- HVOF/HVAF

- Laser Cladding

- PTA

TYPESNickelGlobal97 (B)