Oil & Gas

Built for Extreme Pressures, Proven in the Harshest Environments

The oil and gas industry demands materials that perform under pressure, high heat, and corrosive conditions. For nearly 90 years, Wall Colmonoy has supplied surfacing alloys that protect critical drilling, extraction, and refining equipment from premature wear and failure.

Engineered for outstanding metallurgical performance, our alloys resist abrasion, erosion, galling, and chemical attack – setting the standard for wear protection in demanding oil and gas environments.

Products & Applications

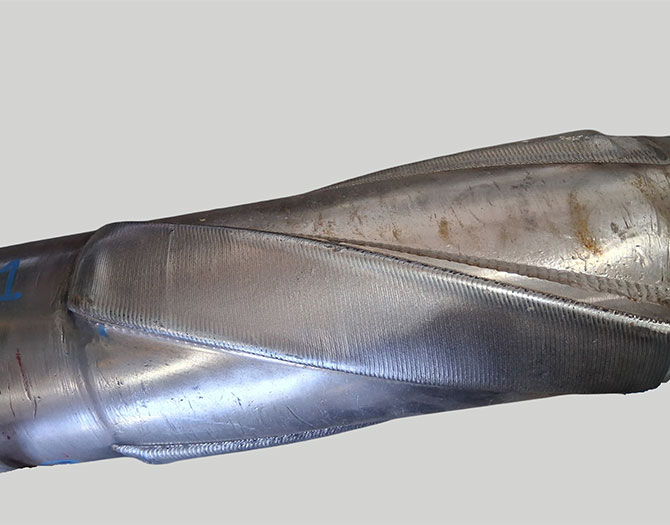

Used across a wide range of components – including compressor rods and sleeves, reamers, plungers, pump shafts, sucker rods, couplings, thermowells, valves, stabilizers, steering pads, drill bits, guides, wear rings, gate and ball valves, seats, regulator and choke valves, plugs, and stab pins – Wall Colmonoy surfacing materials help Oil & Gas equipment last longer and perform more efficiently in service.

Application Methods

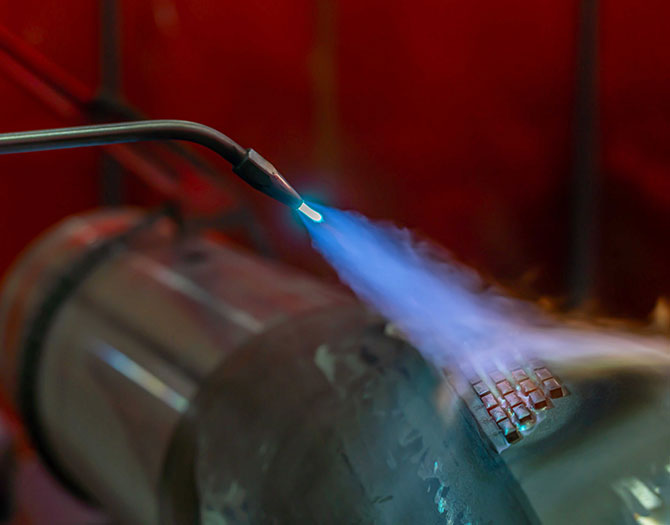

Applied through advanced methods such as Laser Cladding, PTA, HVOF, and Spray & Fuse, our wear-resistant hard-surfacing alloys provide dense, uniform deposits that restore worn parts and strengthen new ones.

Available in powder, rod, or wire form, our alloys are trusted by OEMs and rebuilders worldwide to ensure reliable performance in even the harshest operating environments.

OFW (Oxy-fuel Welding), GMAW (MIG), and GTAW (TIG)

Latest News, Events & Case Studies

Explore the latest news, events, and real-world applications showcasing how Wall Colmonoy delivers solutions to customers’ wear challenges.