Find Your Powder

Our Hardfacing Product Finder tool quickly identifies the ideal solution based on industry, application, and performance requirements.

Filter Results

Found materials matching your search input.

Our Hardfacing Product Finder tool quickly identifies the ideal solution based on industry, application, and performance requirements.

Showing 1–12 of 105 results

-

Colferoloy™ 6005

Iron-Based Powder for Thermal Spray and PTA Welding or Laser Cladding ApplicationsDESCRIPTIONAn economical solution for severe wear environments, extending the lifespan of critical components by providing a combination of abrasion and corrosion resistance.APPLICATION METHODS- Laser Cladding

- PTA

- Thermal Spray / Spraywelder™

TYPESIronGlobal60 min. -

Colferoloy™ SS 316L

Austenitic Stainless Steel Powder for PTA, Laser, and HVOF ApplicationsDESCRIPTIONAustenitic stainless steel containing 2.5% molybdenm with low carbon content and has good resistance to corrosion and high impact, tensile and creep strength at elevated temperatures.APPLICATION METHODS- HVOF/HVAF

- Laser Cladding

- PTA

TYPESIron -

Colmonoy® 45 SW

Crack Resistant Coating Designed for Polymer Quench Applications to Obtain Optimal Properties in Base Metals Such as AISI 4140 and AISI 4340 Type SteelsDESCRIPTIONUsed for thermal spray and fuse application on parts to resist wear, heat, corrosion and galling.APPLICATION METHODSThermal Spray / Spraywelder™TYPESNickelGlobal42-45 -

Colmonoy® 25

Nickel-Based Hard-Surfacing Alloy for Fuseweld™, PTA, and Laser ApplicationsDESCRIPTIONRecommended for hard-surfacing parts for repair of worn or out of tolerance parts.APPLICATION METHODS- Fusewelder™ Torch

- Laser Cladding

- PTA

TYPESNickelWCL25-31 -

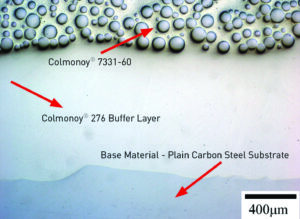

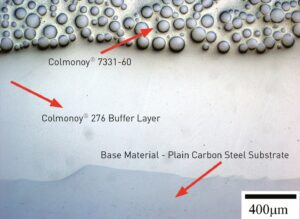

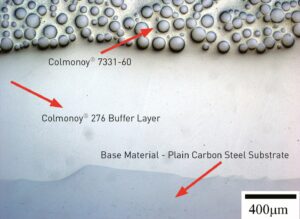

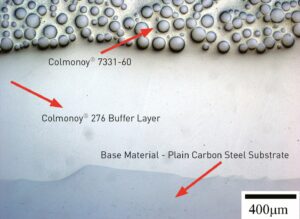

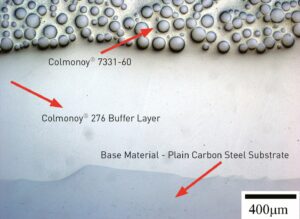

Colmonoy® 276

Nickel-Based Superalloy with High Corrosion ResistanceDESCRIPTIONOffer higher corrosion resistance with excellent pitting resistance and crevice corrosion.APPLICATION METHODS- Additive Manufacturing

- HVOF/HVAF

- Laser Cladding

- PTA

TYPESNickelGlobal99 (B) -

Colmonoy® 276AM

Nickel-Based Superalloy with High Corrosion ResistanceDESCRIPTIONOffer higher corrosion resistance with excellent pitting resistance and crevice corrosion.APPLICATION METHODSAdditive ManufacturingTYPESNickelGlobal99 (B) -

Colmonoy® 276HV

Nickel-Based Superalloy with High Corrosion ResistanceDESCRIPTIONOffer higher corrosion resistance with excellent pitting resistance and crevice corrosion.APPLICATION METHODSHVOF/HVAFTYPESNickelGlobal99 (B) -

Colmonoy® 276L

Nickel-Based Superalloy with High Corrosion ResistanceDESCRIPTIONOffer higher corrosion resistance with excellent pitting resistance and crevice corrosion.APPLICATION METHODS- Laser Cladding

- PTA

TYPESNickelGlobal99 (B) -

Colmonoy® 276PTA

Nickel-Based Superalloy with High Corrosion ResistanceDESCRIPTIONOffer higher corrosion resistance with excellent pitting resistance and crevice corrosion.APPLICATION METHODS- Laser Cladding

- PTA

TYPESNickelGlobal99 (B) -

Colmonoy® 323

Low Melting, Premium Nickel-Based Hard-Surfacing Alloy for Application to Poor Quality Cast Iron and Steel Base MetalsDESCRIPTIONA low melting alloy with excellence wettability on cast irongs and bronze.APPLICATION METHODS- Fusewelder™ Torch

- Thermal Spray / Spraywelder™

TYPESNickelGlobal20-25 -

Colmonoy® 3600

Nickel-Chromium-Molybdenum Powder for PTA & Laser Cladding with Low Magnetic PermeabilityDESCRIPTIONAlloy with moderate hardness and good toughness. It is highly suitable for combining with various hard metals for use in down hole applications where low magnetic permeability in important.APPLICATION METHODS- Laser Cladding

- PTA

TYPESNickelGlobal36 -

Colmonoy® 4001-50 Wire

Nickel-Based Metal Cored Wire With Tungsten Carbide for Improved Wear ResistanceDESCRIPTIONA metal cored wire with deposits that consist of a tough nickel base matrix and exhibit good crack resistance.APPLICATION METHODSHardfacing WireTYPESNickel