PTA Welding Powders

Precision Coatings for Maximum Strength and Service Life

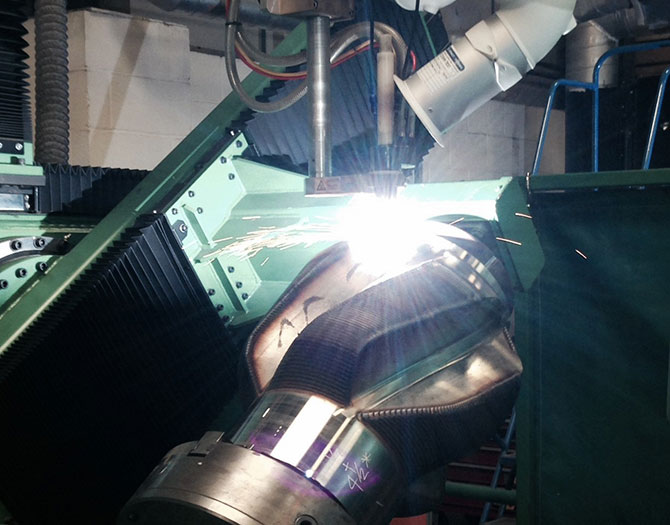

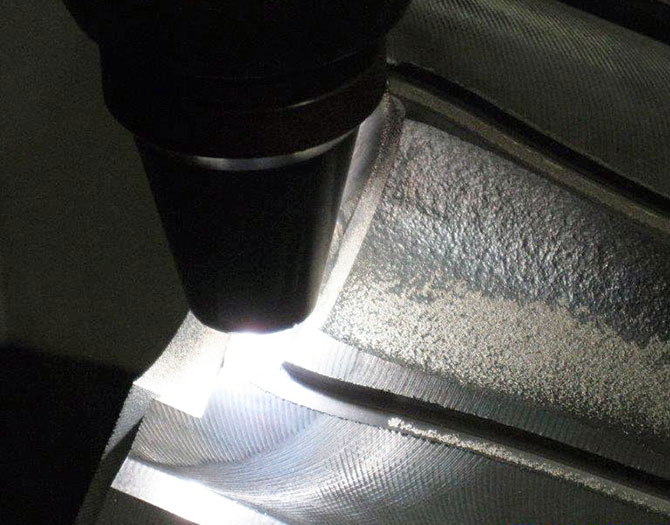

Plasma Transferred Arc (PTA) welding is a high-precision coatings method that produces dense, metallurgically bonded overlays with low dilution and superior wear resistance. Wall Colmonoy’s PTA welding powders are engineered for optimal performance in this advanced application, offering exceptional flow characteristics, stability, and consistency across high-temperature, high-impact environments.

PTA is ideal for surfacing components exposed to intense abrasion, corrosion, or thermal cycling – such as pump shafts, valve seats, plungers, cutting tools, neck rings, molds, guide plates, and more. This process allows for precise control of the weld pool and deposit thickness, delivering coatings that are both extremely durable and tailored to exact application needs.

Products for PTA Welding

Wall Colmonoy’s Colmonoy® nickel-, Wallex® cobalt-, and Colferoloy™ iron-based PTA powders are formulated to deliver clean, consistent deposits with excellent metallurgical bonding and minimal porosity. Available in a range of particle sizes and alloy compositions, our powders are suitable for both general-purpose wear protection and highly specialized environments requiring corrosion or impact resistance.

From legacy equipment repair to critical component manufacturing, our PTA powders provide the strength and precision your operation demands.

Technical Resources

Brochures and selector charts are available to the right. To search for a product, Safety Data Sheet or Case Studies, visit our Resource Library.

Learn more about our comprehensive range of surfacing alloys and their industrial applications.

See at-a-glance details on alloys suited for PTA welding.

Compare alloy performance and selection guidance tailored for PTA and laser applications.