Advanced Alloys for Longer Lasting Parts

Find Your Product

Our Powders

Colmonoy® Nickel-Based Alloys

Wallex® Cobalt-Based Alloys

Colferoloy™ Iron-Based Alloys

WallCarb™ HVOF Powders

Thermal Spray Equipment

Spraywelder™ System

Fusewelder™ Torch

Application Methods

Our hard-surfacing alloys deliver wear and corrosion resistance, extending component service life in demanding industries. Applied through thermal spray, PTA welding, laser cladding, and HVOF, they form durable protective coatings. Advanced methods like HIPping and additive manufacturing further allow for custom material properties and complex geometries.

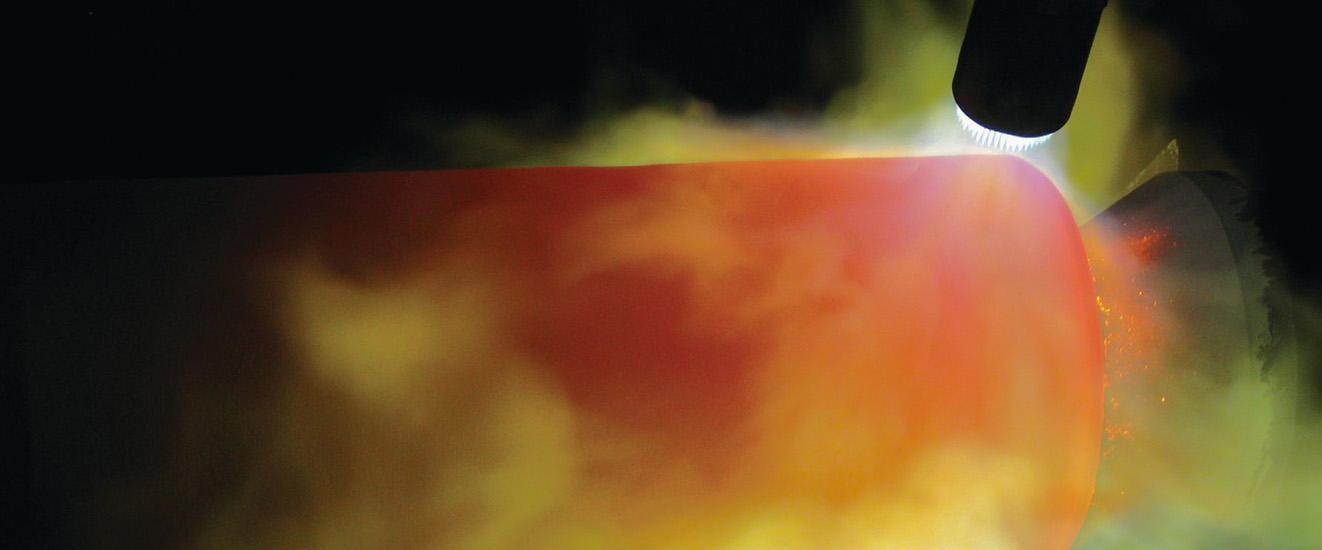

A reliable method for applying wear-resistant coatings with a metallurgical bond, ideal for industrial components.

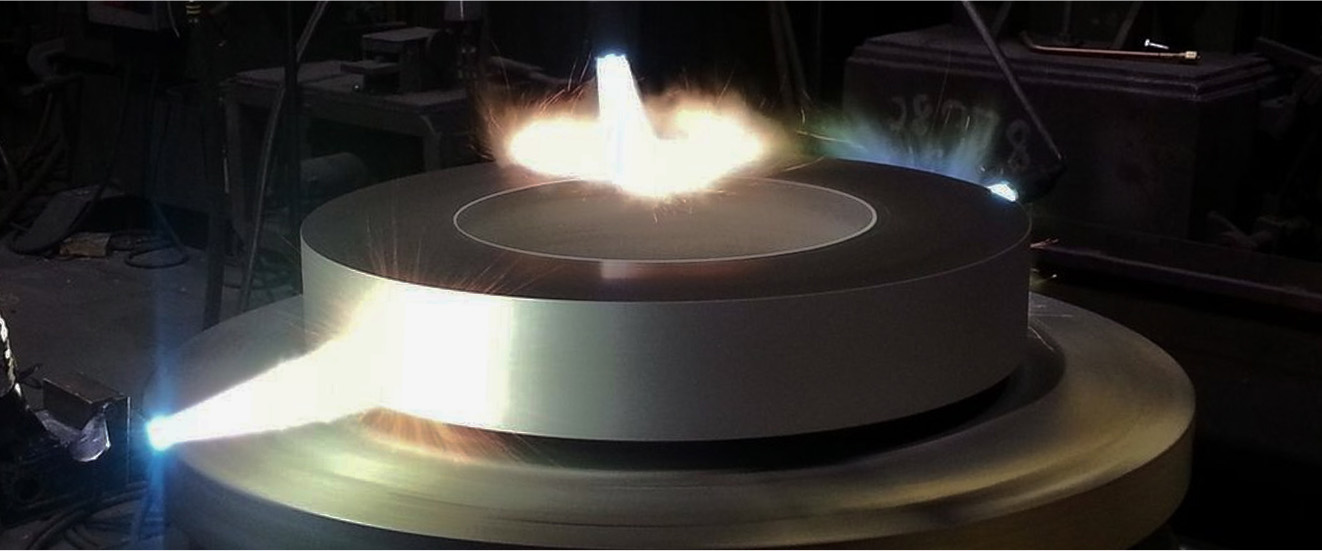

Delivers precision coatings with superior hardness and corrosion resistance, commonly used in high-stress environments.

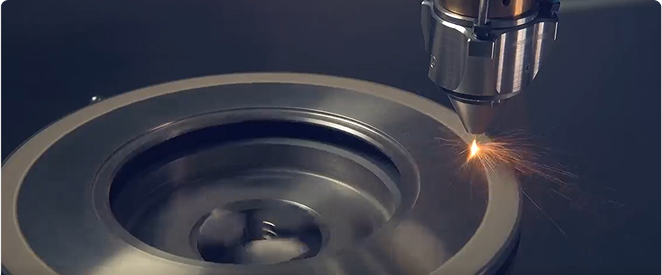

Provides precise, low-dilution coatings with exceptional wear and corrosion resistance, extending the life of critical parts.

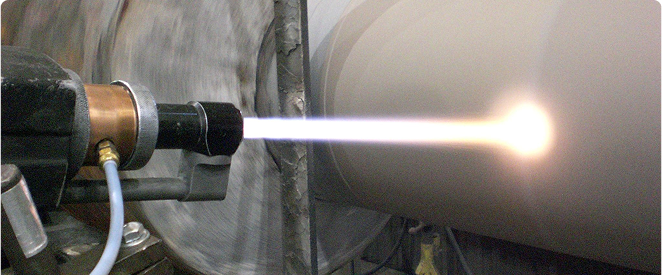

High-velocity application methods that produce dense, hard coatings for superior erosion and corrosion protection.

Designed for hardfacing and repair applications, wires and rods provide extended component life and durability.

Hot Isostatic Pressing (HIP) powders engineered to form fully dense, near-net-shape components with enhanced material properties.

Advanced metal powders optimized for 3D printing applications, enabling high-performance part production with minimal waste.