Our Story

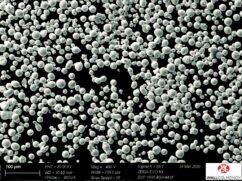

Surfacing Alloys - Making Metals Work Harder Since 1938

Since its founding in 1938 by Albert F. Wall, Wall Colmonoy has led the way in surfacing technology – beginning with the breakthrough Colmonoy® nickel-based alloy invented a year earlier by metallurgists, Norman Cole and Walter Edmonds.

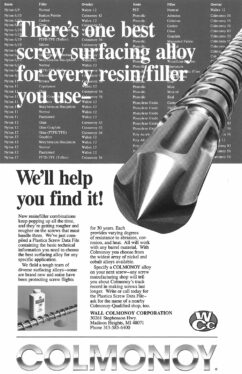

This laid the foundation for a company dedicated to metallurgical innovation – to ‘make metals work harder’. From protecting U.S. Army tank parts in WWII to improving drill bits in the oil industry, our alloys have driven industrial progress worldwide.

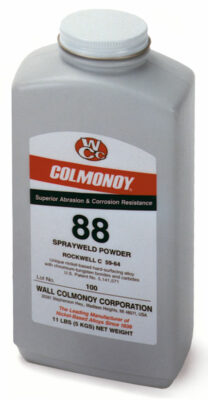

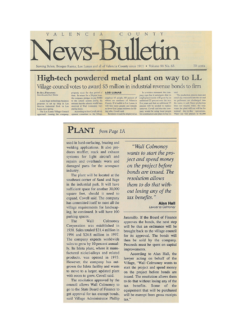

Today, still family-owned and led into its fourth generation, Wall Colmonoy operates across the U.S., U.K., Canada, and Asia – built on a legacy of trust, innovation, and metallurgical expertise. Whether strengthening glass molds, energy turbines, or automotive braking systems, our mission remains the same: to deliver high-performance, wear-resistant solutions.

And as we look ahead, Wall Colmonoy continues investing in advanced alloy manufacturing, R&D, and its team members to meet tomorrow’s industrial wear challenges.

Our Story

Wall Colmonoy’s story is one of innovation, partnership, and progress. Explore our timeline to see how we’ve grown from a breakthrough alloy to a global leader in surfacing solutions.

Experts Behind Every Alloy

Behind every alloy we make is a team of experts – metallurgists, engineers, technical specialists and customer support representatives dedicated to your success.

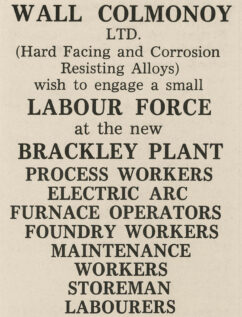

Want to Join Our Team?

Explore our current opportunities.