Steel

Alloys for Steel Industry Wear Challenges

The steel industry depends on equipment that must withstand extreme heat, heavy loads, and abrasion. From blast furnaces and continuous casting to rolling mills and processing lines, components are pushed to their limits every day.

Wall Colmonoy’s surfacing alloys provide protection against thermal and mechanical fatigue, erosion, abrasion, and corrosion; restore worn parts for extended use; and produce dense, uniform layers that improve performance and extend the service life of high-value equipment.

Products & Applications

Applications include equipment for raw material processing, steel making and casting, hot and cold rolling, strip processing and coating – such as rolls, blades, buckets, liners, mold components, continuous casting rolls, and other critical parts. Colmonoy® and Wallex® superalloys help operators achieve greater uptime, longer part life, and enhanced wear properties.

Application Methods

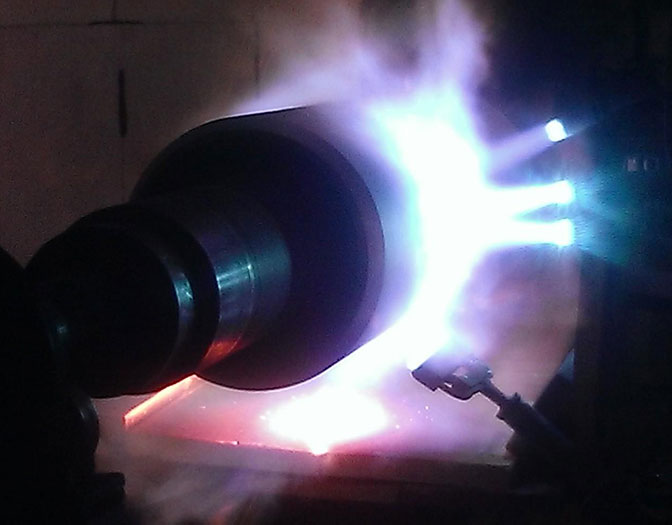

Colmonoy® and Wallex® superalloys are designed for use across a variety of application methods, offering steel manufacturers flexibility in protecting and rebuilding their equipment.

OFW (Oxy-fuel Welding), GMAW (MIG), and GTAW (TIG)

Latest News, Events & Case Studies

Explore the latest news, events, and real-world applications showcasing how Wall Colmonoy delivers solutions to customers’ wear challenges.