Power Generation

Protecting Critical Components from Heat, Wear, and Corrosion

In the demanding world of power generation, equipment failure isn’t an option. Wall Colmonoy’s high-performance Colmonoy®, Wallex®, and Colferoloy™ alloys protect and extend the life of components operating under extreme heat, pressure, and corrosion.

Trusted by leading producers across thermal, nuclear, biomass, and waste-to-energy plants, our alloys deliver resistance to wear and high-temperature oxidation – keeping systems online and minimizing costly downtime.

Products & Applications

Wall Colmonoy’s range of nickel-, cobalt-, and iron-based surfacing alloys are ideal for protecting boiler tubes, burner tips, soot blower lances, and rotating valves from erosion, thermal fatigue, and corrosive gas exposure.

Application Methods

Whether you’re generating energy from fossil fuels, steam, or waste, we provide the technical expertise, alloy customization, and application support you need to keep your equipment running at peak performance.

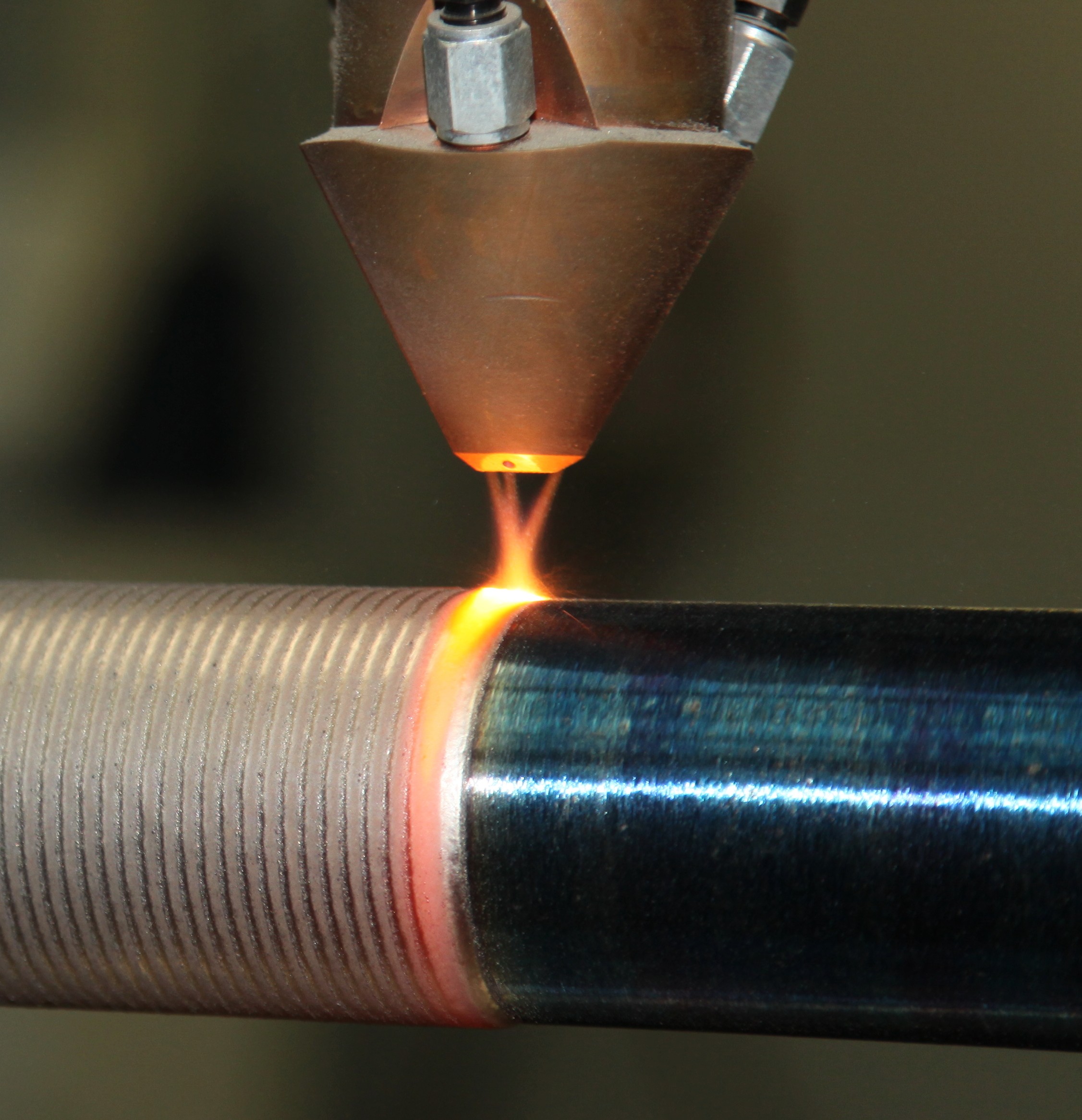

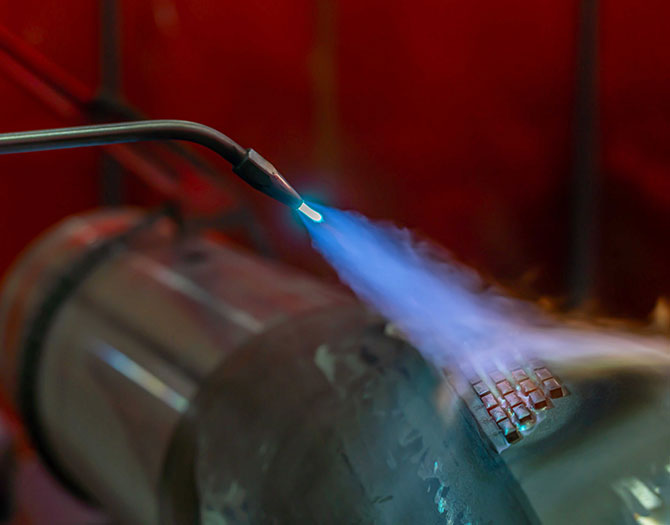

Wall Colmonoy offers a range of nickel-, cobalt-, and iron-based surfacing alloys for use in laser cladding, PTA, HVOF, Spray & Fuse, HIPping and Additive Manufacturing processes.

OFW (Oxy-fuel Welding), GMAW (MIG), and GTAW (TIG)

Latest News, Events & Case Studies

Explore the latest news, events, and real-world applications showcasing how Wall Colmonoy delivers solutions to customers’ wear challenges.