Mining

Engineered to Keep You Mining

In mining, equipment failure isn’t just inconvenient – it’s costly. That’s why Wall Colmonoy delivers high-performance surfacing alloys designed to extend the life of components exposed to abrasion, heavy impact, and corrosive environments. From hard rock, mineral, dredging, and quarrying operations to material handling, our Colmonoy® nickel-based and Wallex® cobalt-based alloys keep your operation running longer, stronger, and more efficiently.

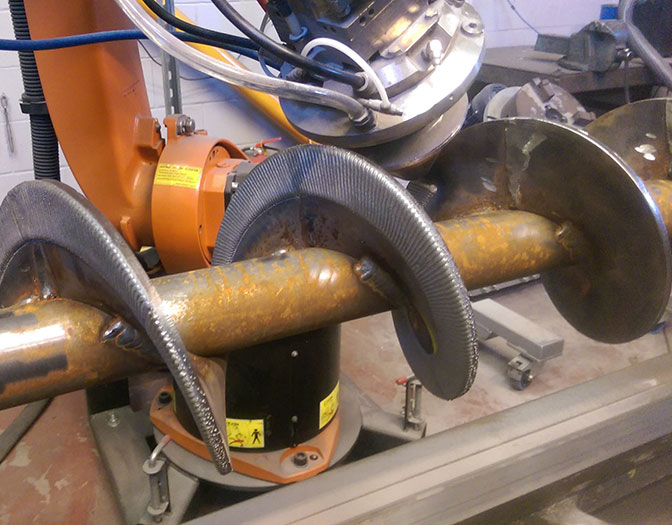

We understand the wear mechanisms at work in crushers, shredders, augers, mills, pumps, and chutes. Our alloys are specifically formulated to withstand the forces that shorten mining component life – helping reduce downtime, cut maintenance costs, and improve productivity. Whether you need defense against sliding abrasion, impact erosion, or chemical attack, our team brings unmatched metallurgical expertise and hands-on technical support to ensure you get the right solution for your toughest challenges.

Products & Applications

From digging teeth and crushers to conveyors, wear plates, and hydraulic components – Colmonoy® and Wallex® alloys protect mining, quarrying, and aggregate systems from abrasion, impact, and corrosion, keeping you productive longer.

Application Methods

Wall Colmonoy offers nickel- and cobalt-based hardfacing alloys designed for Fuseweld™, Sprayweld™, PTA, Laser Cladding, HVOF, OFW (Oxy-fuel Welding), GMAW (MIG), and GTAW (TIG) applications – ideal for extending the life of high-wear mining components such as digging teeth, wear plates, impact liners, crushers, mills, conveyors, separators and other ore processing tools.

Our powders and wires are engineered to perform in abrasive and corrosive environments, providing maximum resistance with minimal porosity and superior bond strength.

OFW (Oxy-fuel Welding), GMAW (MIG), and GTAW (TIG)

Latest News, Events & Case Studies

Explore the latest news, events, and real-world applications showcasing how Wall Colmonoy delivers solutions to customers’ wear challenges.