Thermal Spray Powders (Spray & Fuse)

Dense & Durable, Metallurgically Bonded Coatings

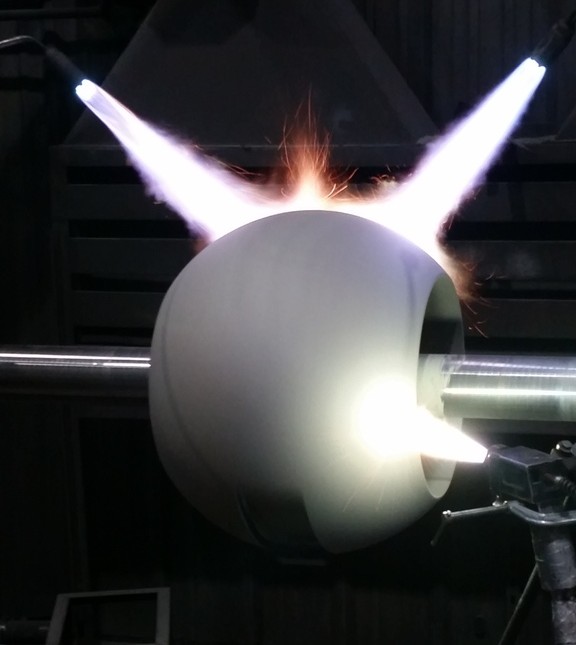

For industries demanding high-strength wear protection, thermal spray & fused coatings offer a quick and cost-efficient solution that delivers dense, metallurgically bonded, low-porosity coatings with exceptional durability. Wall Colmonoy’s thermal spray powders are specially engineered for this application method – ensuring consistent flow, strong adhesion, and optimal fusing across a wide range of industrial parts and surfaces.

Ideal for parts exposed to abrasive wear, sliding contact, or corrosive environments, Spray & Fuse coatings are commonly used in the oil & gas, petroleum, chemical processing, power generation, waste-to-energy, automotive, rubber & plastic, agriculture, and glass container industries on various applications like pump sleeves, shafts, impellers, valve seats, mixing blades, extruders, neck rings, glass moulds, drill bits, stabilisers, steering pads, frack pump plungers/pistons, and many more.

Products for Spray & Fuse Applications

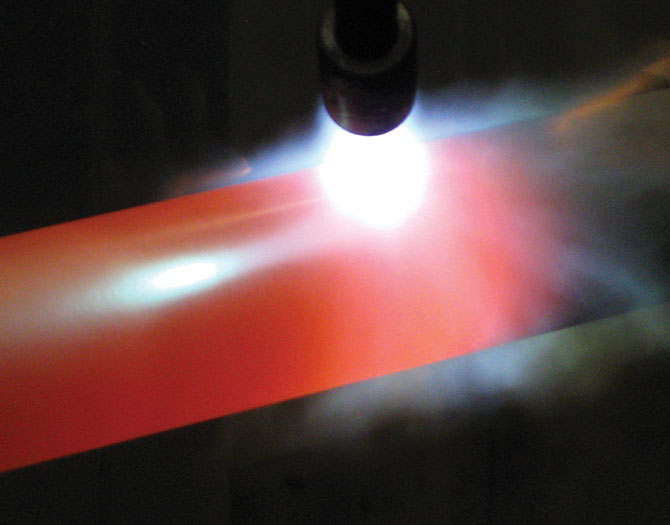

Wall Colmonoy offers self-fluxing (containing Boron and Silicon) nickel- and cobalt-based powders formulated specifically for Spray & Fuse processes. These powders are designed to flow smoothly through our Spraywelder™ System and Fusewelder™ Torch to deliver strong, uniform coatings with excellent wear and corrosion resistance.

Whether you need general-purpose overlays or tailored solutions for extreme wear application and corrosive environments, our wear-resistant powders are available in a variety of particle sizes and chemistries to suit your application needs.

Technical Resources

Brochures and selector charts are available to the right. To search for a product, Safety Data Sheet or Case Studies, visit our Resource Library.

Explore our full portfolio of surfacing alloys designed to improve wear and corrosion resistance.

Quickly compare alloy options to find the right fit for your thermal spray application.

Review alloy recommendations and performance characteristics for PTA and laser cladding processes.

Identify the optimal powders for HVOF and HVAF spray applications with this quick-reference chart.